CASE: Exhaust valve seal in diesel engine of considerable size

Generic o-rings made of materials like FPM and NBR are often the default choice for constructing and securing machinery due to their familiarity and affordability. However, despite their low cost, they can lead to significant downtime if they fail. As small components, o-rings play a vital role in the overall functioning of the machine, and their failure can result in the machine’s complete breakdown.

CASE: Exhaust valve seal in diesel engine of considerable size

In the context of a heavy industry client, a challenge arose concerning a large diesel engine. The seal between a major exhaust valve and the engine was initially constructed using a generic FPM O-ring. While the operating conditions of the engine were not extreme, with a maximum pressure of 7 bar and temperatures below 100 degrees in its water-cooled, semi-static, and vibration-prone environment, there was a crucial requirement for uninterrupted 24/7 operation. Any downtime would have severe financial implications for the company.

CASE: Exhaust valve seal in diesel engine of considerable size

In the context of a heavy industry client, a challenge arose concerning a large diesel engine. The seal between a major exhaust valve and the engine was initially constructed using a generic FPM O-ring. While the operating conditions of the engine were not extreme, with a maximum pressure of 7 bar and temperatures below 100 degrees in its water-cooled, semi-static, and vibration-prone environment, there was a crucial requirement for uninterrupted 24/7 operation. Any downtime would have severe financial implications for the company.

To ensure the reliability of the client’s engine, we opted to design a specialized seal using our product called DanaFlex H. DanaFlex H was chosen specifically because it offers an infinite service life under the unique conditions of the engine. To optimize the mounting of the seal, Dana-Seals collaborated with the customer to develop custom profiles tailored to their specific needs.

By implementing the DanaFlex H seal and closely monitoring its service life, we aimed to provide a reliable solution that would mitigate the risk of downtime and ensure continuous operation of the client’s diesel engine.

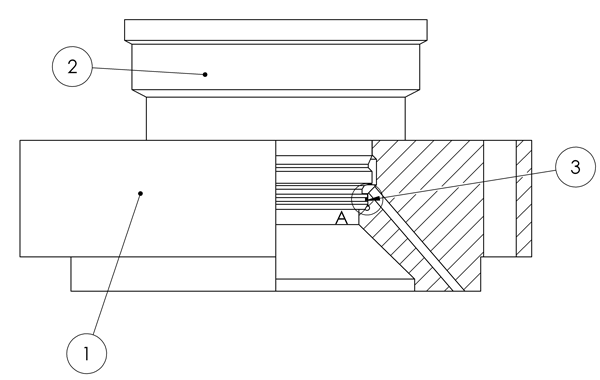

Exhaust valve seat seal in big diesel engine

fig.1:

Item No | Part number | QTY. |

|---|---|---|

1 | Engine block | 1 |

2 | Valve | 1 |

3 | Seal | 1 |

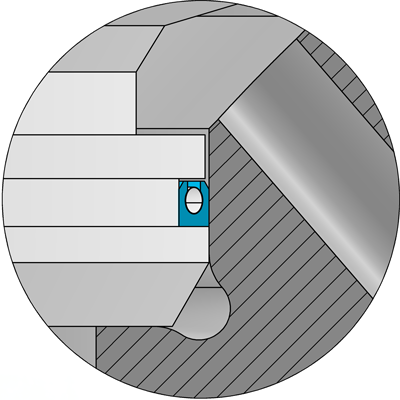

Fig.2:

Ⓒ 2024 - All Rights Are Reserved

Please fill in the form below and we would appreciate it if you attach eventual drawings of hardware or seals to clarify technical demands.