Dana-Seals A/S

Products & Materials

Dana-Seals specialises in state-of-the-art seals in PTFE and engineering plastics. We manufacture a wide range of application solutions in collaboration with numerous producers of hydraulic and pneumatic equipment. Our seals are regarded as among the best in the industry in terms of high quality and technical performance

Standard and customised applications

Dana-Seals produce reliable, high-performance seals in sizes Ø3mm – Ø3000mm. We develop and deliver both standard and custom-designed products.

DanaFlon compound

Product categories include:

- Rod Line – Seals for reciprocating applications with the seal face applied on the inside

- Piston Line – Seals for reciprocating applications with the seal face applied on the outside

- Roto Line – Seals for rotary applications with the seal face applied on the inside and outside

- Scraper Line – Protection systems for the Rod Line and custom-designed sealing systems

- Face Seals – For static and dynamic applications to seal between the inside and outside diameter

- Wear Rings – For stand-alone load applications or as a part of a sealing system

DanaFlon compound

PTFE - the many advantages of polytetrafluoro-ethylene

Seals made from PTFE (polytetrafluoroethylene) are used where many other sealing materials, like e.g., elastomers, PUR and fabric materials fail to meet the necessary temperature range, chemical resistance or friction, and wear requirements.

Excellent electrical properties

PTFE

Advantages connected to PTFE

- Reduced stick-slip

- Unlimited shelf life

- No explosive decompression

- Excellent electrical properties

- Safe for use in vacuum conditions

- No swelling due to moisture absorption

- Suitable for contact with food and complies with all FDA requirements

- Low friction/dry running capability – PTFE has the lowest friction coefficient of any known solid

- Extreme chemical resistance. Only few media are known to react with PTFE: alkaline metals, fluorine and a few fluorochemicals, such as chlorine trifluoride and oxygen difluoride

- Thermal stability across a wide temperature range. PTFE can be used continuously at service temperatures of up to 260°C. PTFE can also be used at cryogenic temperatures to seal critical media, such as liquid nitrogen (-196°C)

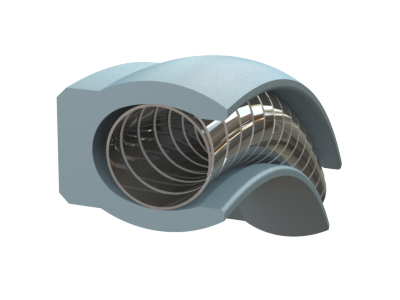

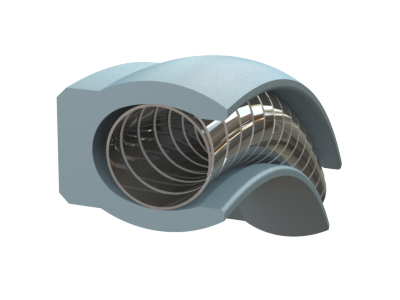

Energizers

Springs and O-rings

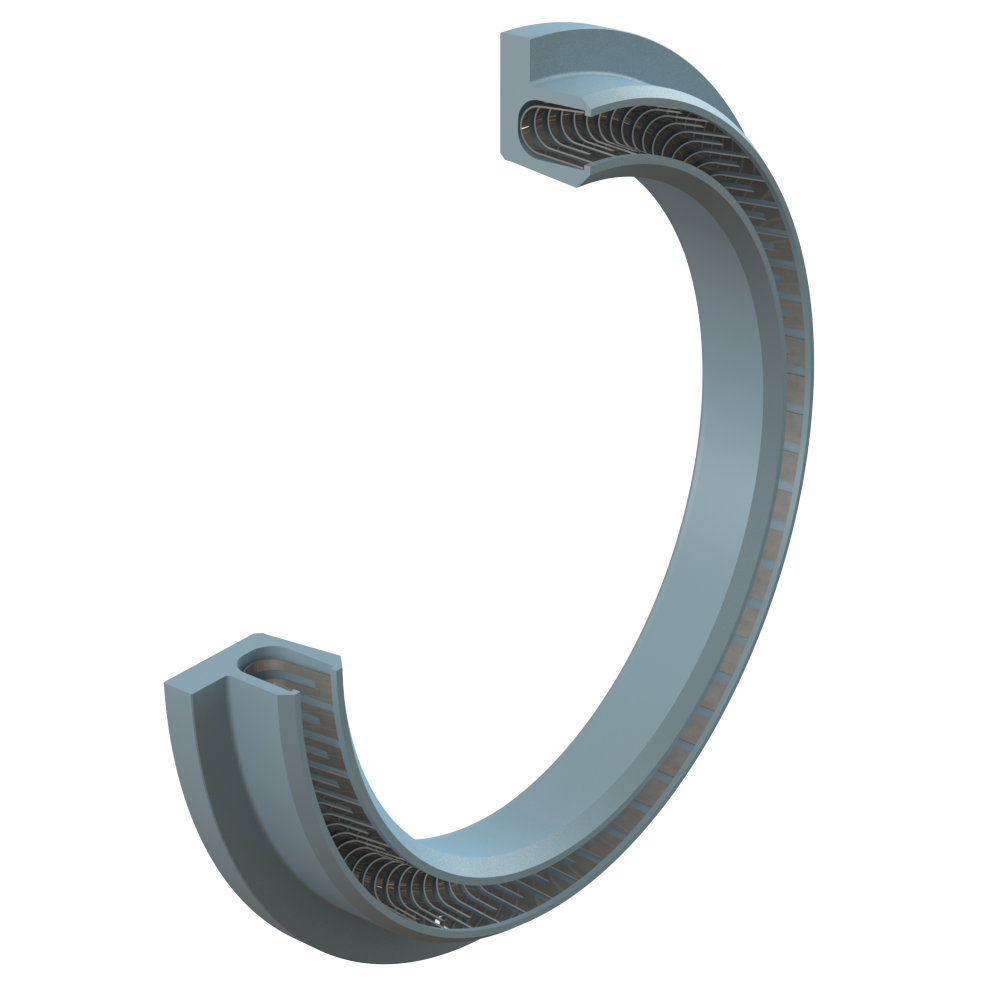

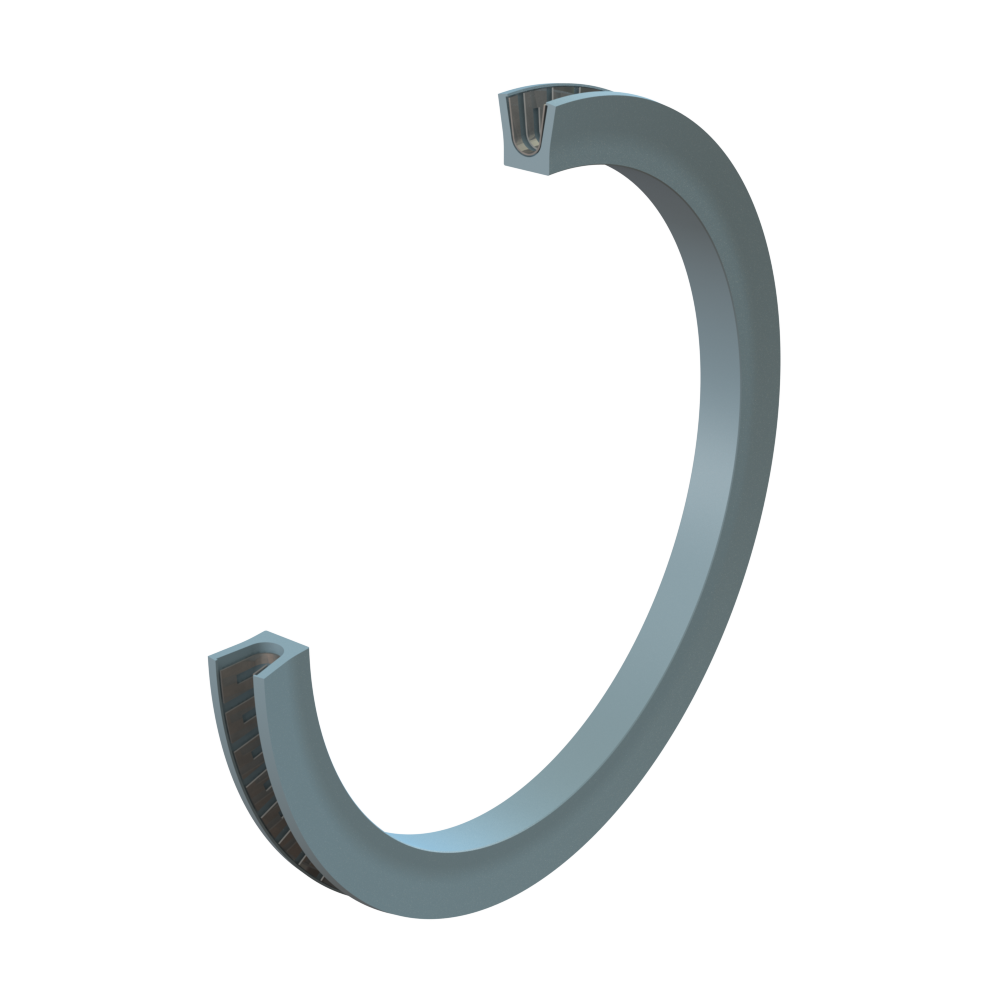

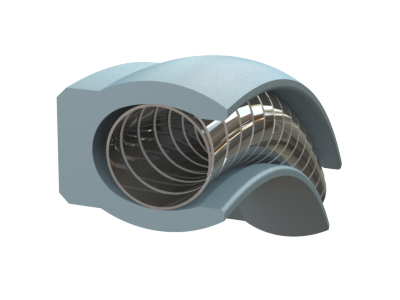

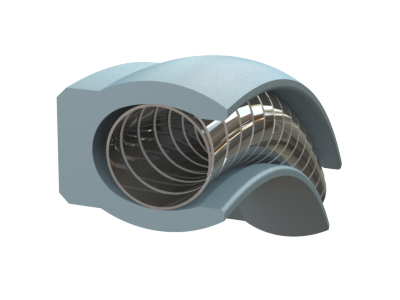

PTFE-compound based seals typically need to be energized by metal springs or rubber O-rings. Dana-Seals develop and produce V-springs and helical springs in-house, to optimize design and properties for the individual application. When requested, we can also apply springs from approved suppliers.

O-rings from approved suppliers are delivered with the sealing solution when requested.

Energizers

Springs and O-rings

PTFE-compound based seals typically need to be energized by metal springs or rubber O-rings. Dana-Seals develop and produce V-springs and helical springs in-house, to optimize design and properties for the individual application. When requested, we can also apply springs from approved suppliers.

O-rings from approved suppliers are delivered with the sealing solution when requested.

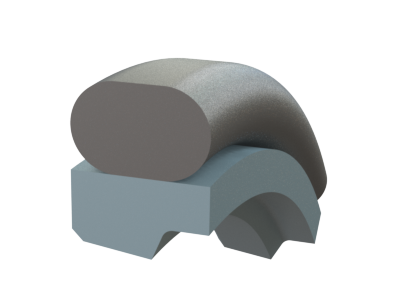

From standard to extreme conditions

Spring energized seal

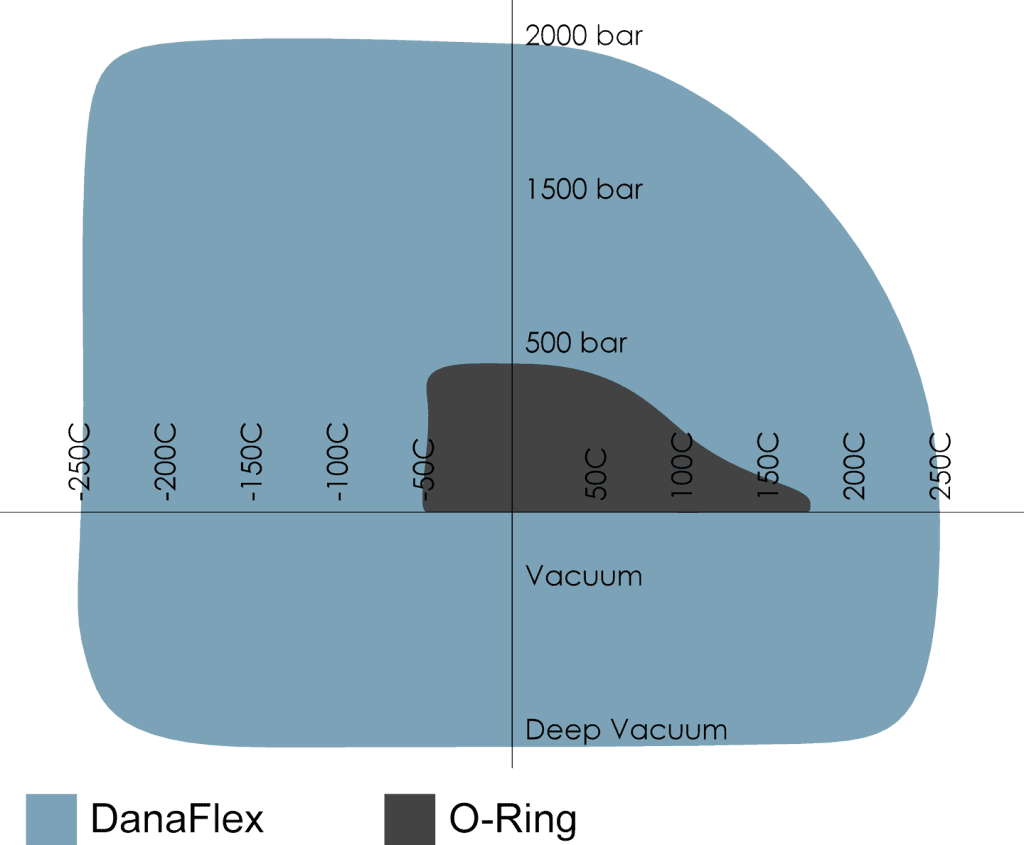

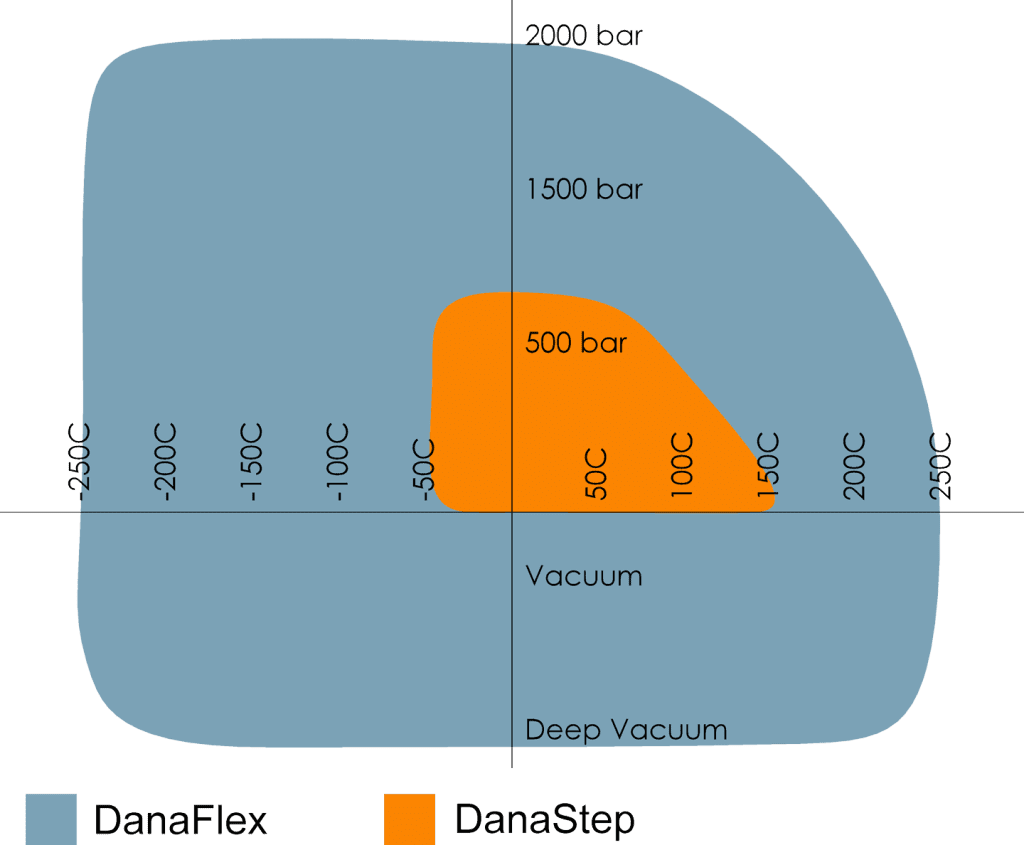

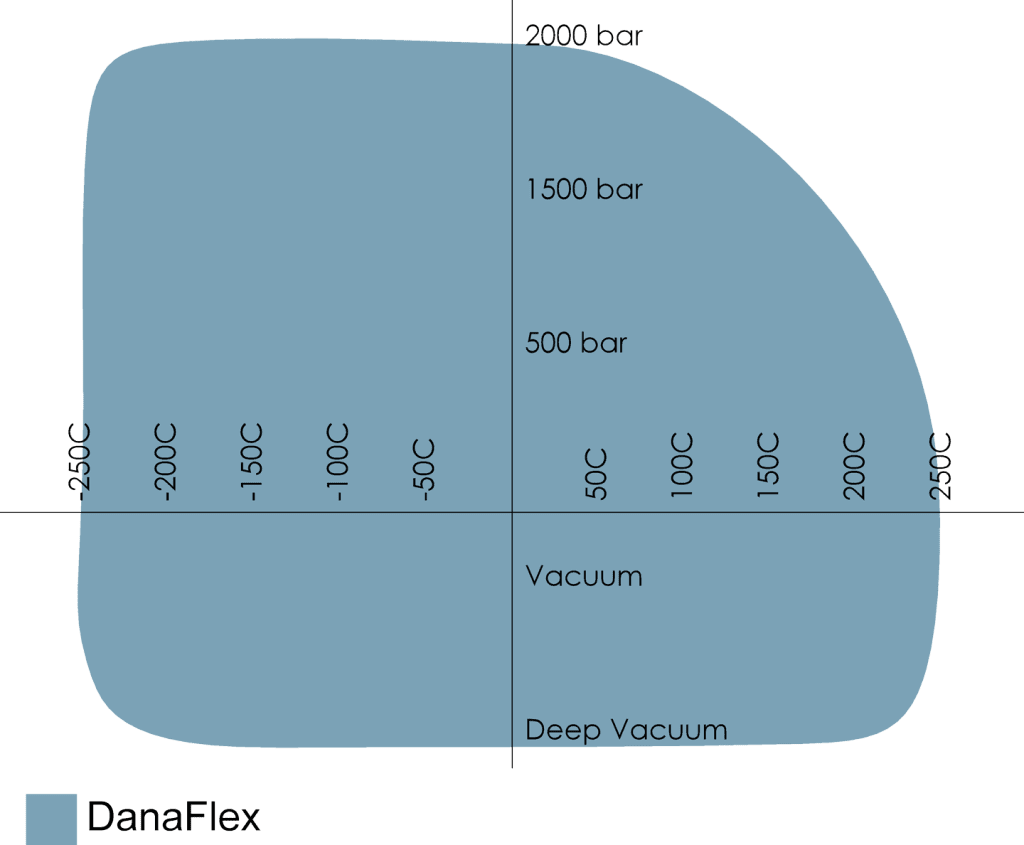

For elevated pressure, temperature, chemical aggressive media, or other challenges, our DanaFlex seal is recommended. The standard groove dimensions for DanaFlex are according to AS4716/ISO 6194, which is typical O-ring groove dimensions.

For special groove dimensions, DanaFlex can be specially designed and produced without mould or other start-up cost. The delivery time for special DanaFlex is the same as for standard products. Please see examples of simple and dynamic applications below.

Excellent electrical properties

From standard to extreme conditions

Simple Static applications

O-rings are unique seals for simple static applications working with limited pressure, temperature and types of media. Dana-Seals do not produce O-rings, but we can as trade product supply O-rings together with our advanced sealing systems.

For elevated pressure, temperature, chemical aggressive media or other challenges, DanaFlex is recommended. The standard groove dimensions for DanaFlex are according to AS4716/ISO 6194 which is typical O-ring groove dimensions.

For special groove dimensions DanaFlex can be special designed and produced without mould or other start-up cost. The delivery time for special DanaFlex is the same as for standard products.

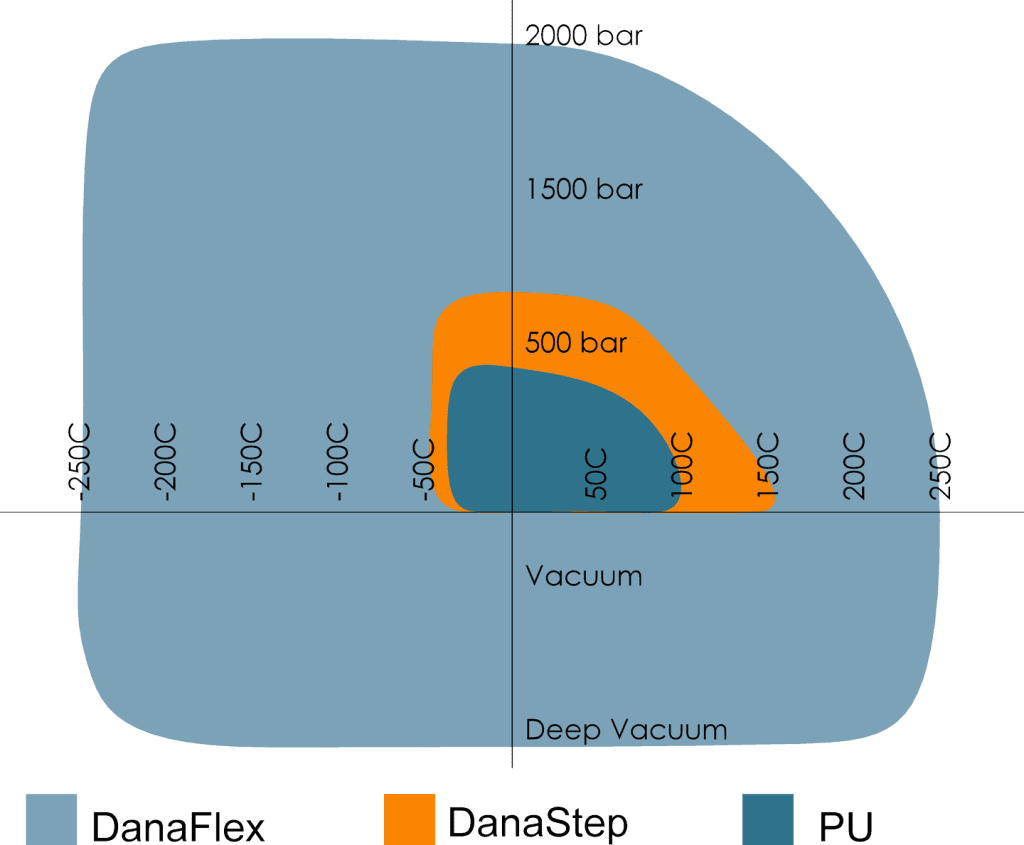

From standard to extreme conditions

Dynamic reciprocating applications

Lubricating media not chemical aggressive

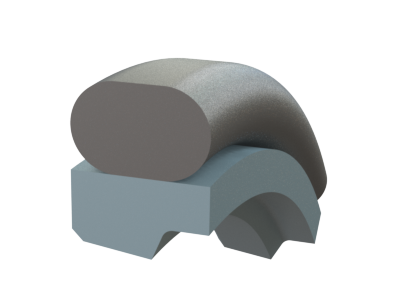

Dynamic applications require advanced seals like polyurethane u-cups, DanaStep and DanaGlide seal types or even DanaFlex. Groove dimensions for DanaStep and DanaGlide types are typically according to ISO 7425-1 and 7425-2.

Based on the working conditions for your application, we make a proposal. For that, we need information about the working conditions such as pressure profile, temperature profile, media, movement and sketch or drawing of the hardware. Our proposals include choice of seals and recommendation for the hardware.

From standard to extreme conditions

Non lubricating media not chemical aggressive

When there is a wide range of conditions, like e.g. non lubricating media, demand for low friction, small space for the sealing system, precise movement with no stick slip, elevated or low temperature or elevated pressure you typically need seal types like DanaStep and DanaGlide. Groove dimensions typically according to ISO 7425-1 and 7425-2.

O-rings

Non lubricating media chemical aggressive

For the hardest conditions with a broad range of temperature, media, movement and geometrical challenges DanaFlex types offers the outmost possibilities.

Looking for a seal for complex condition, that you are not able to find in our catalogue? Please contact us. We are eager to give you the best possible guidance and proposal for a unique sealing solution to meet your needs.

Technical support

Innovative quality

All our seals can be produced in a variety of materials

Inhouse development, local production, and full traceability

- High performance and optimized cost-benefits are the foundation of the design process

- Quality levels are described and controlled through ISO 9001 certification

- Continuous improvement of production processes, advanced sealing solutions and new materials to fit your technical challenges

- Seal design, PTFE-compounding, and production procedures developed and optimised in-house

- Seal production ranges from Ø3mm – Ø3000mm, based on high-quality CNC technology

- Isostatic tubes moulding up to Ø580mm

- Full production cycle and R&D based in Elsinore, Denmark

Delivery times

Our delivery is primarily make-to-order

Our flexibility provides a range of delivery options in diameters Ø3-Ø580

- Standard delivery within 3 – 4 weeks

- If urgent, delivery within 2 weeks. Delivery fee can occur.

- If urgent, and if feasible within our production schedule, delivery within 2 – 5 working days. Delivery fee can occur.

- Contact us for delivery options for diameters larger than Ø560.

FAQ

Here are some of the questions we are frequently being asked. If you have other questions to Dana-Seals products and production, do not hesitate to contact us.

Dana-Seals makes a wide range of standard and customized seals for hydraulic applications.

- Hydraulic cylinder seal

- Hydraulic piston seal

- Hydraulic rod seal

- Hydraulic wiper seal

- Hydraulic scrapers

- Hydraulic wear rings

- Hydraulic guide rings

No. The delivery time is the same for standard and special seals.

Spring activated u-cups are one of Dana-Seals’ specialities. We make both the DanaFlon PTFE compounds and the springs in-house. Our standard spring material is AISI316L EN 1.4404, which provides high chemical resistance.

The following materials are compatible with food contact and have been tested and approved in accordance with the requirements set out in the EU 10/2011

Virgin PTFE (DF10),

PTFE with Ekonol (DF12)

UHMWPE – Ultra High Molecular Weight Polyethylene (DF91, DF98)

Further DF91 and DF98 complies with FDA

DF98 has also 3A dairy

Other special materials for food applications are available on request

Our sealing application sizes varies from ø3mm to ø3000mm. All types of sealing design are available in the whole diameter range.

Let us help you find the right solution

Office, production and test lab

- Dana-Seals A/S

- Ole Rømers Vej 4G

- DK-3000 Helsingør

- Denmark

- info@dana-seals.dk

- +45 4922 4400

-

CVR: 26 16 54 58

Please feel free to contact us with any queries you might have

Monday to Thursday: 8am – 4pm GMT+1

Friday: 8am – 3pm GMT+1