CASE: Seal for LNG-environment in the maritime industry

CASE: Seal for LNG-environment in the maritime industry

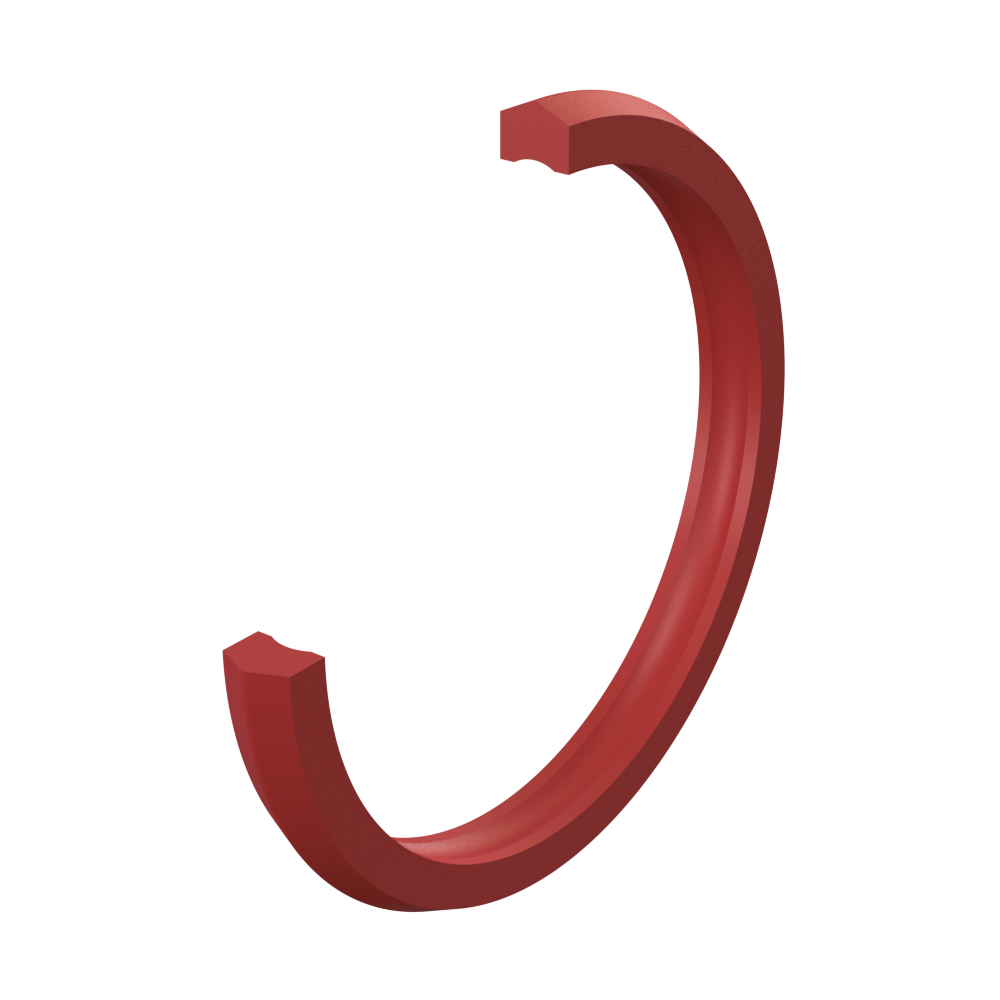

Engineers in the maritime industry often face limitations when using traditional o-rings, especially in applications with challenging conditions or non-standard groove dimensions. Dana-Seals A/S understands these challenges and has successfully engineered DanaCover, a double-acting seal designed to withstand high pressures. Its optimized material selection and innovative design make it ideal even for demanding LNG environments.

CASE: Seal for LNG-environment in the maritime industry

Engineers in the maritime industry often face limitations when using traditional o-rings, especially in applications with challenging conditions or non-standard groove dimensions. Dana-Seals A/S understands these challenges and has successfully engineered DanaCover, a double-acting seal designed to withstand high pressures. Its optimized material selection and innovative design make it ideal even for demanding LNG environments.

A client in the maritime industry turned to Dana-Seals when they experienced decompressive explosions using traditional o-rings in a fuel unit for Liquid Natural Gas (LNG). Existing market options for double-acting seals did not meet the required groove dimensions or working conditions. To address this challenge, we developed DanaCover. This seal, based on DanaFlon 85, 95 shore a polyurethane material, offers exceptional resistance against decompressive explosions. Unlike traditional o-rings, DanaCover is bent like a beam, reducing its sensitivity to compression-set. This unique design approach overcomes the limitations associated with high-hardness materials.

Dana-Seals A/S optimized the manufacturing process of DanaCover to ensure flexibility and efficiency. Unlike traditional polyurethane profile rings that require specific molds for each dimension, DanaCover can be machined to any required dimension without the need for additional time and cost associated with mold production. Leveraging design software and extensive experience, Dana-Seals can rapidly produce DanaCover in any dimension, providing a quick and customized sealing solution to meet specific application requirements.

Ⓒ 2024 - All Rights Are Reserved

Please fill in the form below and we would appreciate it if you attach eventual drawings of hardware or seals to clarify technical demands.