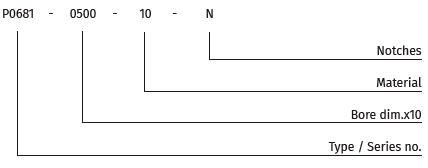

Dana X Seal heavy P068

Dana X Seal heavy is the heavy-duty version of the Dana X Seal. The Dana X Seal combines the Dana Glide qualities low friction, long service life and no stick-slip with the static sealing effect of a Quad-Ring® and is particularly suitable for applications where 100% static sealing effect is required for an extended duration. Dana X Seal heavy provides the same features as the Dana X Seal, but with a much enhanced form stability against extrusion. Dana X Seal heavy is typically used in applications where a big metallic clearance is required. To ensure that the profile ring is pressure activated even in conditions with rapid pressure changes, the seal is delivered with notches.

Advantages:

- High dynamic and static sealing effect

- High extrusion resistance

- Low friction

- No stick-slip

- Small groove

- High operational stability

- Suitable for a wide variety of media

Application Examples

- Mobile hydraulics

- Standard cylinders

- Machine tools

- Injection moulding machines

- Presses

- Servo cylinders

Working conditions:

- Pressure: 50 Mpa

- Temperature: NBR O-ring: -30 to +100 FPM O-ring: -10 to +200

- Application: High pressure, Intensive movement

- Speed: 3 m/s

- Standard: ISO 7425-2

- Diameter range: 40 to 700 mm

- Action: Double-acting

Frequently used Material DanaFlon | |||||

|---|---|---|---|---|---|

Operating temperature range | –200 to +260 °C | –200 to +260 °C | –200 to +260 °C | ||

Basis material | PTFE | Modified PTFE | PTFE | ||

DanaFlon | 24 | 45 | 32 | ||

Filler | Bronze & Additives | Carbon fibre | Carbon & Graphite | ||

Colour | Brownish | Dark Gray | Dark Black | ||

Extreme form stability and extrusion resistance | Yes | Yes | (Yes) | ||

Lubricating media | Yes | Yes | Yes | ||

Extreme wear resistance | (Yes) | (Yes) | (Yes) | ||

Wide range of media | No | Yes | Yes | ||

Non-lubricating media | No | Yes | Yes | ||

Food applications | No | No | No | ||

Conforms to food regulation | No | No | No | ||

Frequently used Material DanaFlon | |||||

|---|---|---|---|---|---|

Operating temperature range | –200 to +260 °C | –200 to +260 °C | –60 to +60 °C Short duration: 135 °C | ||

Basis material | PTFE | PTFE | UHMWPE | ||

DanaFlon | 16 | 55 | 98 | ||

Filler | Mineral & MoS2 | Glass & MoS2 | Virgin | ||

Colour | Blue / Gray | Light Gray | White | ||

Extreme form stability and extrusion resistance | (Yes) | (Yes) | (Yes) | ||

Lubricating media | Yes | Yes | Yes | ||

Extreme wear resistance | (Yes) | (Yes) | Yes | ||

Wide range of media | Yes | Yes | Yes | ||

Non-lubricating media | Yes | Yes | Yes | ||

Food applications | No | No | Yes | ||

Conforms to food regulation | No | No | FDA, 3A Dairy,

EU 10/2011 | ||

The Rubber-Profile-Rings may limit the temperature range and need to be compatible with the media.

The performance of the seal will always depend on the total picture of working conditions.

Verifying the performance of the seal can only be done by test at the actual working conditions.

Dana X Seal heavy P068

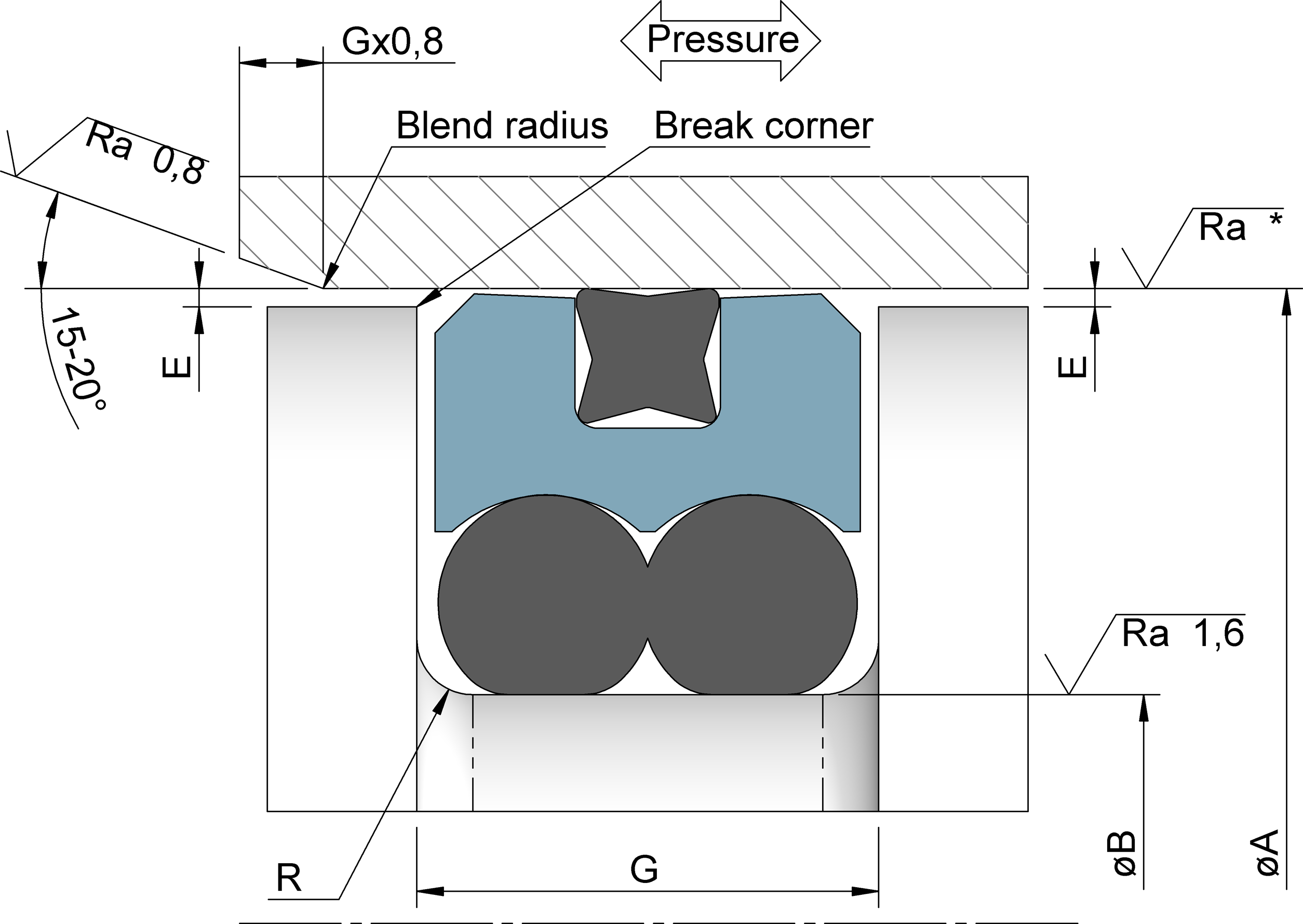

Technical details

Here you can see the technical details

-

Ra max (0.2 μm)

-

Rz max (1.25 μm)

-

Rp max (0.63 μm)

-

Tp = 50 - 70% at depth of p= 0.25 Rz

Heading #3 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Series | Bore Diameter øA H9 | Groove

Diameter | Groove

witdth | Radius | Radius Clearance | O-Ring

Cross

Section | Quad-Ring

Cross

Standard Section | ||||

Standard Section

Appilcation | Available Range | øB h9 | G + 0,2– 0 | Rmax | 10 MPa | 20 MPa | 30 MPa | ||||

P06 | 81 | 40 – 79,9 | 25 – 250 | øA – 10 | 6,3 | 0,6 | 0,30 | 0,20 | 0,15 | 2,62 | 1,78 |

82 | 80 – 132.9 | 50 – 450 | øA – 13 | 8,3 | 1,0 | 0,40 | 0,30 | 0,15 | 3,53 | 2,62 | |

83 | 133 – 462,9 | 100 – 650 | øA – 18 | 12,3 | 1,3 | 0,40 | 0,30 | 0,20 | 5,33 | 3,53 | |

84 | 463 – 700,0 | 425 – 700 | øA – 31 | 16,3 | 1,8 | 0,50 | 0,40 | 0,30 | 7,00 | 5,33 | |

Max radial clearance is based on DanaFlon 24 and 100 °C. For other hi-filled Danaflon compounds the clearance should be reduced with 10%.

Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.