Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.

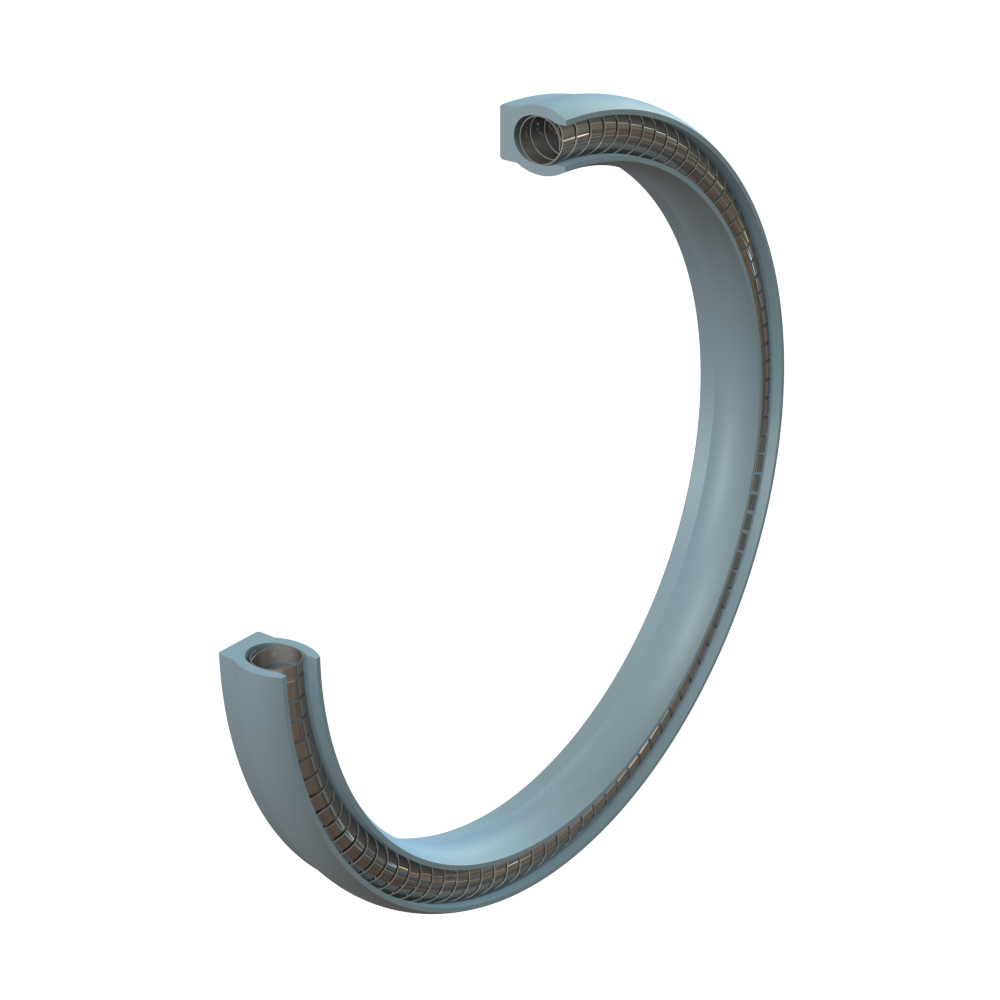

DanaFlex H Static is designed for high sealing efficiency, even in cryogenic applications.

It consists of a PTFE-based material activated by a AISI 316L stainless steel spring with high chemical resistance. The spring is helical, which maximises the spring force.

Thanks to this design, it has durable elasticity throughout the lifetime, regardless of medium, temperature and application.

Excellent electrical properties

Advantages:

APPLICATION EXAMPLES

Working conditions:

| Static and semi-dynamic applications | –200 to +260 °C | –200 to +260 °C |

| Basis material | PTFE | PTFE |

| DanaFlon | 10 | 18 |

| Filler | Virgin | Additives |

| Colour | White | Blue |

| Sealing against gas | yes | yes |

| Wide range of media | yes | yes |

| Lubricating media | yes | yes |

| Non-lubricating media | yes | yes |

| Food applications | yes | yes |

| Conforms to food regulation | 10/2011/EC | no |

| Extreme wear resistance | no | no |

| Extreme form stability and extrusion resistance | no | no |

| Static and semi-dynamic applications | –200 to +260 °C | –200 to +260 °C |

| Basis material | PTFE TFM | PTFE |

| DanaFlon | 11 | 61 |

| Filler | Virgin modified | MoS2 |

| Colour | White | Blue/Gray |

| Sealing against gas | yes | yes |

| Wide range of media | yes | yes |

| Lubricating media | yes | yes |

| Non-lubricating media | yes | yes |

| Food applications | yes | no |

| Conforms to food regulation | no | no |

| Extreme wear resistance | no | no |

| Extreme form stability and extrusion resistance | no | no |

The performance of the seal will always depend on the overall picture of the working conditions.

Verification can only be done by testing the seal in the actual working conditions.

DanaFlex H Static R63

Here you can see the technical details

| Series | Rod

øB h9 |

øA h11 | L | G + 0,2- 0 | Rmax | E Radial Clearance | X | ||||

| <2 Mpa | <10 Mpa | <20 Mpa | <40 Mpa | min. | |||||||

| R63 | 01 | 12 - 19,9 | øB + 4,5 | 2,25 | 3,60 | 0,4 | 0,25 | 0,15 | 0,10 | 0,07 | 0,7 |

| 02 | 20 - 39,9 | øB + 6,2 | 3,10 | 4,80 | 0,6 | 0,35 | 0,20 | 0,15 | 0,08 | 1,0 | |

| 03 | 40 - 119,9 | øB + 9,4 | 4,70 | 7,10 | 0,8 | 0,50 | 0,25 | 0,20 | 0,10 | 1,5 | |

| 04 | 120 - 600,0 | øB + 12,2 | 6,10 | 9,50 | 0,8 | 0,60 | 0,30 | 0,25 | 0,12 | 1,9 | |

| 11 | 12 - 19,9 | øB + 4,5 | 2,25 | 4,65 | 0,4 | 0,25 | 0,15 | 0,10 | 0,07 | *0,7 | |

| 12 | 20 - 39,9 | øB + 6,2 | 3,10 | 5,70 | 0,6 | 0,35 | 0,20 | 0,15 | 0,08 | *1,0 | |

| 13 | 40 - 119,9 | øB + 9,4 | 4,70 | 8,50 | 0,8 | 0,50 | 0,25 | 0,20 | 0,10 | *1,5 | |

| 14 | 120 - 600,0 | øB + 12,2 | 6,10 | 11,20 | 0,8 | 0,60 | 0,30 | 0,25 | 0,12 | *1,9 | |

*NB: Longer G

Spring material

S = AISI 316L. EN 1.4404

E = 2.4711 (Elgiloy)

Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.

Ⓒ 2024 - All Rights Are Reserved

Please fill in the form below and we would appreciate it if you attach eventual drawings of hardware or seals to clarify technical demands.