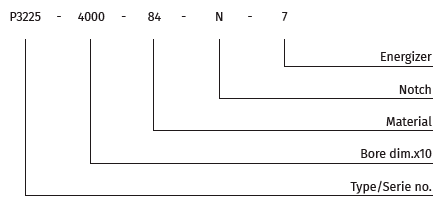

DanaGlide HI-pressure PU P322

DanaGlide HI-Pressure is designed for applications where you need the low friction of conventional Glide-rings of PTFE compounds combined with the robustness of polyurethan.

The energizer is a special square rubber element. The square element secures correct placement in the groove.

Advantages:

- Robust seal for ISO 7424-1

- Abrasion resistance

- Low friction

- Small groove

- Suitable for hydraulic fluids

Applications Examples

- Heavy hydraulic cylinders

Working conditions:

- Pressure: 40 Mpa

- Temperature: NBR O-ring: -30 to +80

- Application: High pressure, Intensive movement

- Speed: 1 m/s

- Diameter range: 40 to *3000 mm

- Action: Double-acting

- Seals larger than 2000mm please contact us for design details

Frequently used Material DanaFlon | |||||

|---|---|---|---|---|---|

Operating temperature range | –60 to +80 °C 60 Shore D | –60 to +80 °C 70 Shore D | |||

Basis material | Polyurethane | Polyurethane | |||

DanaFlon | 84 | 86 | |||

Filler | Virgin | Virgin | |||

Colour | Red | Black | |||

Extreme form stability and extrusion resistance | (Yes) | Yes | |||

Lubricating media | Yes | Yes | |||

Extreme wear resistance | (Yes) | (Yes) | |||

Wide range of media | Yes | Yes | |||

Non-lubricating media | Yes | Yes | |||

Food applications | No | No | |||

Conforms to food regulation | No | No | |||

The Rubber-Profile-Rings may limit the temperature range and need to be compatible with the media.

The performance of the seal will always depend on the total picture of working conditions.

Verifying the performance of the seal can only be done by test at the actual working conditions.

DanaGlide HI-pressure PU P322

Technical details

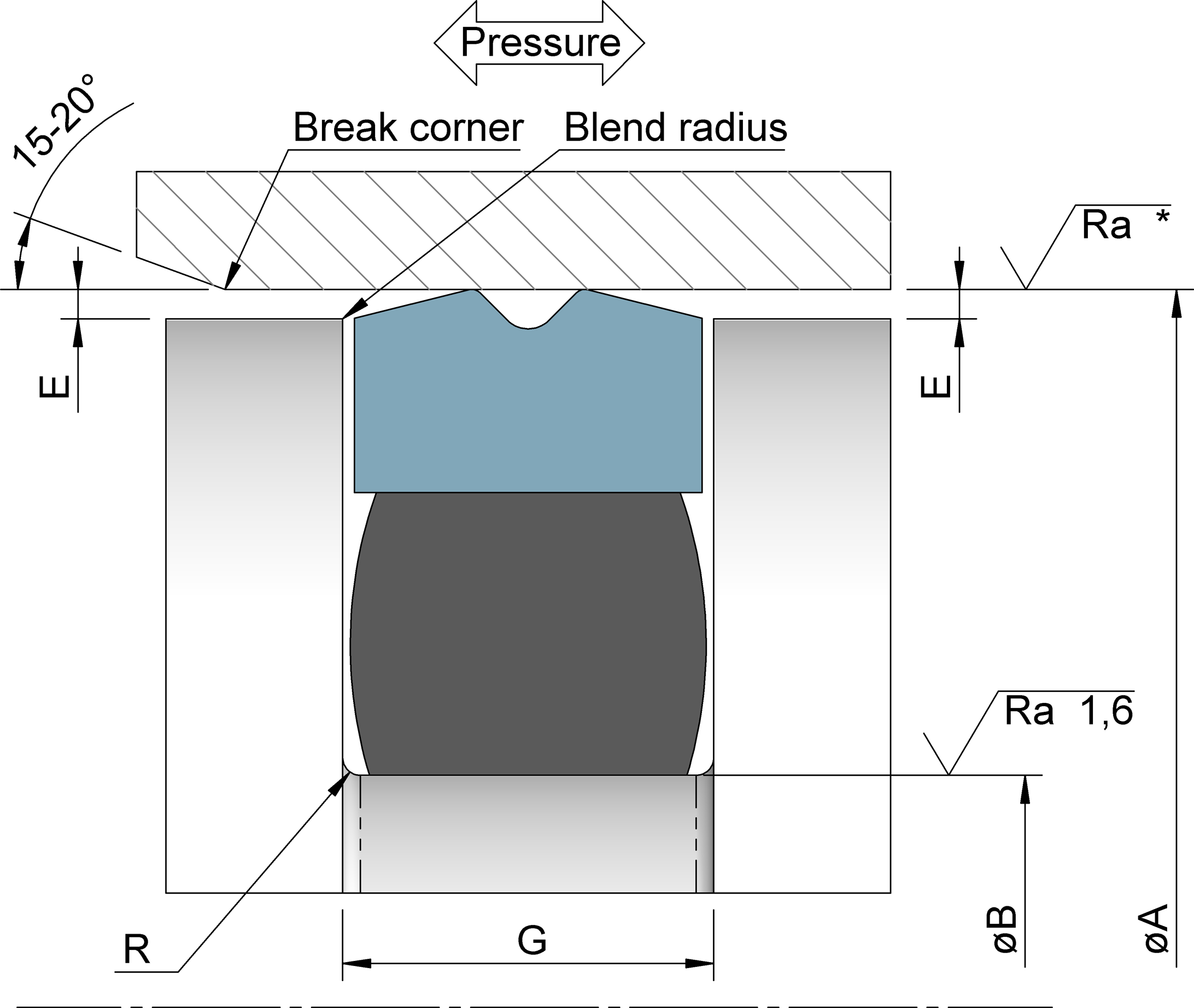

Here you can see the technical details

-

Ra max (0.2 μm)

-

Rz max (1.25 μm)

-

Rp max (0.63 μm)

-

Tp = 50 - 70% at depth of p= 0.25 Rz

Heading #3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Serie | Bore | øB h9 | G + 0,2– 0 | R | Max radial Clearance | |||||

øA H9 | 16 MPa | 26 MPa | 32 MPa | 40 MPa | ||||||

P32 | 23 | 40 – 330 | øA – 15,5 | 6,3 | 0,3 | 0,55 | 0,45 | 0,40 | 0,35 | |

24 | 80 – 670 | øA – 21,0 | 8,1 | 0,4 | 0,60 | 0,50 | 0,45 | 0,45 | ||

25 | 133 – 1000 | øA – 24,5 | 8,1 | 0,4 | 0,70 | 0,60 | 0,55 | 0,50 | ||

26 | 330 – 2000 | øA – 28,0 | 9,5 | 0,5 | 0,75 | 0,65 | 0,60 | 0,50 | ||

7 NBR

Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.