DanaRoto S pressure relieved R41

DanaRoto is a PTFE-based sealing system. It consists of a PTFE sealing ring, thanks to which there is a low level of friction on and wear of the rotating surface, and an elastomeric O-ring, which activates the PTFE cap and ensures the sealing on the static side is leaktight. The recompressed O-ring provides the sealing function at low pressures, and when the application is pressurised, the O-ring puts more pressure on the PTFE cap, thus enhancing the sealing performance. Stick-slip-free performance is guaranteed by the material properties of the PTFE cap. ø DanaRoto is a double-acting system, which means that there is no preferred pressure direction.

The rod seal family provides a sealing effect between the rotating surface and the inner diameter of the seal.

Advantages:

- Pressure relief

- Low friction

- Small groove

- High wear resistance

- Excellent form stability

Application Examples

- Swivel joints

Working conditions:

- Pressure: 40 Mpa

- Temperature: NBR O-ring: -30 to +100 FPM O-ring: -10 to +200

- Application: Pivot movement

- Speed: 1 m/s

- Standard: ISO 7425-1

- Diameter range: 6 to *1200 mm

- Action: Double-acting

- Seals larger than 1000 mm please contact us for design details

Frequently used Material DanaFlon | |||||

|---|---|---|---|---|---|

Operating temperature range | –200 to +260 °C | –200 to +260 °C | |||

Basis material | PTFE | PTFE | |||

DanaFlon | 55 | 32 | |||

Filler | Glass & MoS2 | Carbon & Graphite | |||

Colour | Light Gray | Dark Black | |||

Extreme form stability and extrusion resistance | (Yes) | (Yes) | |||

Lubricating media | Yes | Yes | |||

Extreme wear resistance | (Yes) | (Yes) | |||

Wide range of media | Yes | Yes | |||

Non-lubricating media | Yes | Yes | |||

Food applications | No | No | |||

Conforms to food regulation | No | No | |||

Frequently used Material DanaFlon | |||||

|---|---|---|---|---|---|

Operating temperature range | –200 to +260 °C | –200 to +260 °C | |||

Basis material | PTFE | PTFE | |||

DanaFlon | 41 | 16 | |||

Filler | Carbon fibre | Mineral & MoS2 | |||

Colour | Dark gray | Blue / Gray | |||

Extreme form stability and extrusion resistance | (Yes) | (Yes) | |||

Lubricating media | Yes | Yes | |||

Extreme wear resistance | (Yes) | (Yes) | |||

Wide range of media | Yes | Yes | |||

Non-lubricating media | Yes | Yes | |||

Food applications | No | No | |||

Conforms to food regulation | No | No | |||

O-rings may limit the temperature range and need to be compatible with the media.

The performance of the seal will always depend on the overall picture of the working conditions.

Verification can only be done by testing the seal in the actual working conditions.

DanaRoto S pressure relieved R41

Technical details

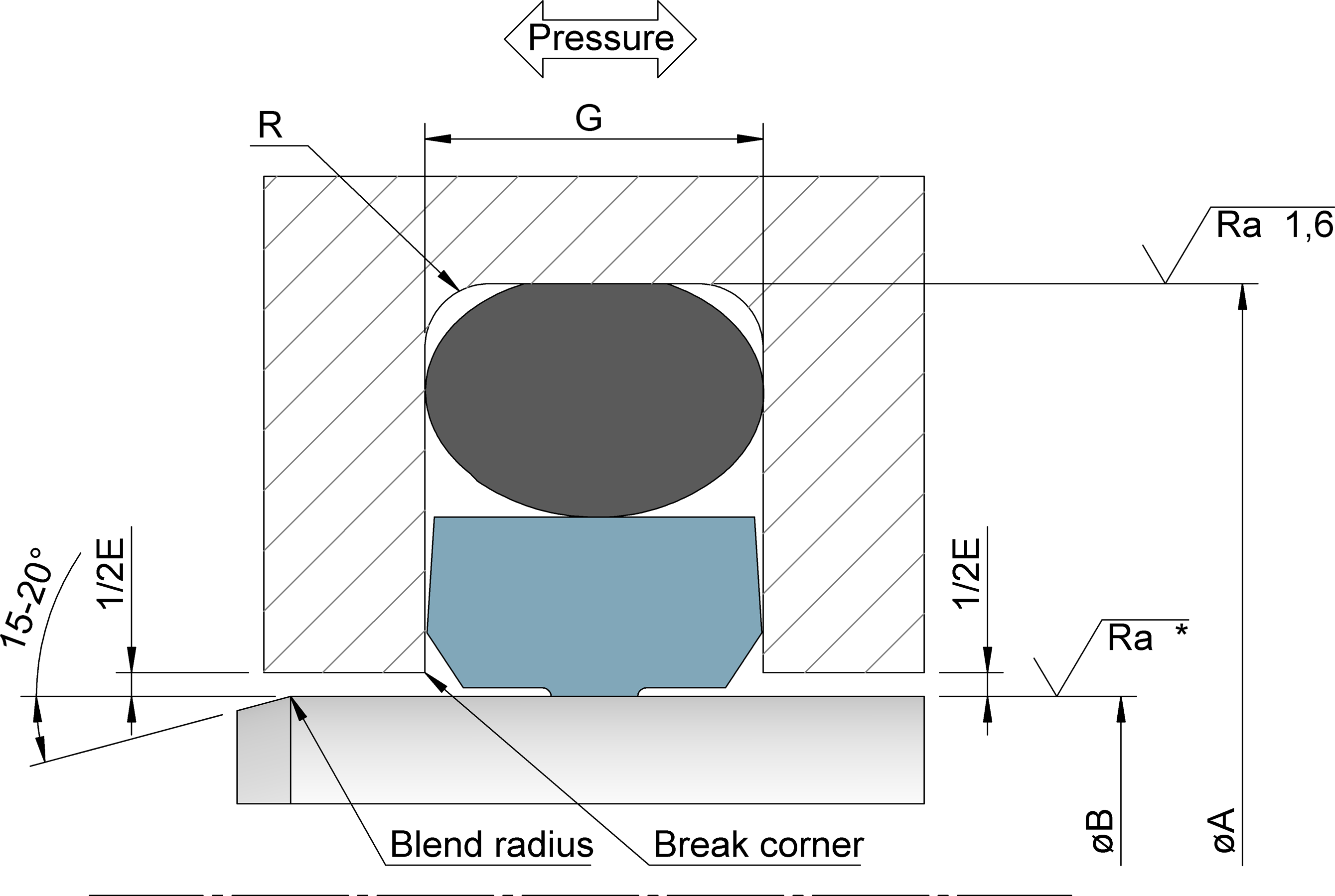

Here you can see the technical details

An appropriate quality of the dynamic counterface is essential for good results. A surface hardness of 55-60 HRC is recommended for a hard layer with thickness min. 0,5 mm.

-

Ra max (0.2 μm)

-

Rz max (1.25 μm)

-

Rp max (0.63 μm)

-

Tp = 50 - 70% at depth of p= 0.25 Rz

Heading #3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Series | Rod øB f8/h9 | øA H9 | G + 0,2– 0 | Rmax | E Diametral Clearance | O-Ring | ||||

100 bar | 200 bar | Serie | Cross sect. | |||||||

max. | max. | |||||||||

R41 | 00 | 6 – 24,9 | øB + 4,9 | 2,2 | 0,4 | 0,15 | 0,10 | 000 | 1,78 | |

01 | 25 – 59,9 | øB + 7,5 | 3,2 | 0,6 | 0,20 | 0,15 | 100 | 2,62 | ||

02 | 60 – 132,9 | øB + 11,0 | 4,2 | 1,0 | 0,25 | 0,20 | 200 | 3,53 | ||

03 | 133 – 329,9 | øB + 15,5 | 6,3 | 1,3 | 0,30 | 0,25 | 300 | 5,33 | ||

04 | 330 – 654,9 | øB + 21,0 | 8,1 | 1,8 | 0,35 | 0,25 | 400 | 7,00 | ||

05 | 655 – 999,9 | øB + 28,0 | 9,5 | 2,5 | 0,45 | 0,30 | – | 8,40 | ||

Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.