DanaStep R21

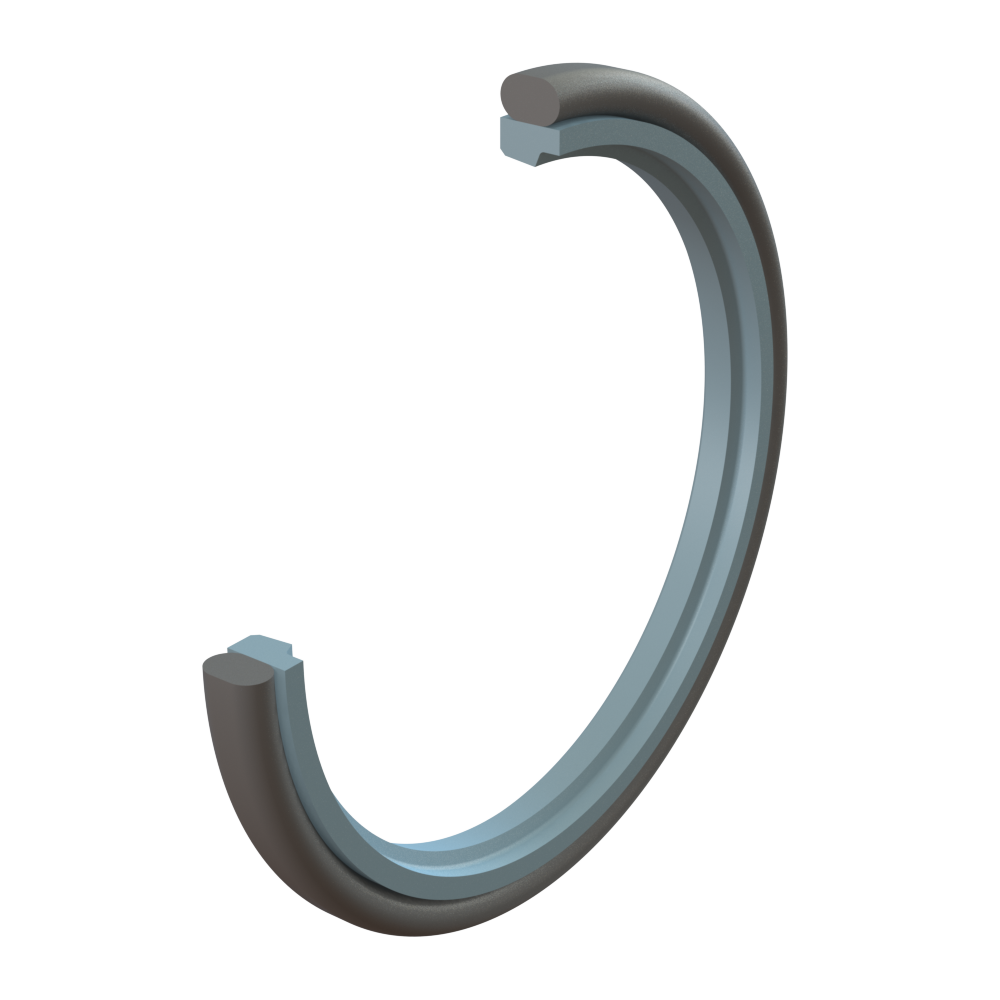

DanaStep is designed with the well-known profile that enables the seal to draw liquid back into the system. With two Dana Steps in tandem combined with a double wiper, there is zero leakage in almost any application. The radius of the rear of the seal secures optimal form stability.

A combination with DanaFlon compounds with maximum form stability provides the best possible safety. The DanaFlon materials are chemically resistant to all hydraulic media and the O-ring material can be chosen so that the seal is unaffected by the media.

Excellent electrical properties

Advantages:

- High dynamic and static sealing effect

- High extrusion resistance

- Low friction

- No stick-slip

- Small groove

- High operational stability

- Suitable for a wide variety of media

APPLICATION EXAMPLES

- Mobile hydraulics

- Standard cylinders

- Machine tools

- Injection moulding machines

- Presses

- Servo cylinders

Working conditions:

- Pressure: 80 Mpa

- Temperature: NBR O-ring: -30 to +100 FPM O-ring: -10 to +200

- Application: High pressure, Intensive movement

- Speed: 15 m/s

- Standard: ISO 7425-2

- Diameter range: 3 to *3000 mm

- Action: Single-acting

- Seals larger than 1000 mm please contact us for design details

| Intensive movement - High pressure | –200 to +260 °C | –200 to +260 °C | –200 to +260 °C |

| Basis material | PTFE | PTFE TFM | PTFE |

| DanaFlon | 24 | 45 | 32 |

| Filler | Bronze & Additives | Carbon fibre | Carbon & Graphite |

| Colour | Brownish | Dark Gray | Dark Black |

| Extreme form stability and extrusion resistance | yes | yes | (yes) |

| Lubricating media | yes | yes | yes |

| Extreme wear resistance | (yes) | (yes) | (yes) |

| Wide range of media | no | yes | yes |

| Non-lubricating media | no | yes | yes |

| Food applications | no | no | no |

| Conforms to food regulation | no | no | no |

| Intensive movement - High pressure | –200 to +260 °C | –200 to +260 °C | –200 to +260 °C | –60 to +60 °C Short duration: 120 °C |

–60 to +60 °C Short duration: 135 °C |

| Basis material | PTFE | PTFE | PTFE | UHMWPE | UHMWPE |

| DanaFlon | 41 | 16 | 55 | 91 | 98 |

| Filler | Carbon fibre | Mineral & MoS2 | Glass & MoS2 | Virgin | Virgin |

| Colour | Dark gray | Blue / Gray | Light Gray | White | White |

| Extreme form stability and extrusion resistance | (yes) | (yes) | (yes) | (yes) | (yes) |

| Lubricating media | yes | yes | yes | yes | yes |

| Extreme wear resistance | (yes) | (yes) | (yes) | yes | yes |

| Wide range of media | yes | yes | yes | yes | yes |

| Non-lubricating media | yes | yes | yes | yes | yes |

| Food applications | no | no | no | yes | yes |

| Conforms to food regulation | no | no | no | FDA, EU 10/2011 | FDA, 3A Dairy, EU 10/2011 |

O-rings may limit the temperature range and need to be compatible with the media.

The performance of the seal will always depend on the overall picture of the working conditions.

Verification can only be done by testing the seal in the actual working conditions.

DanaStep R21

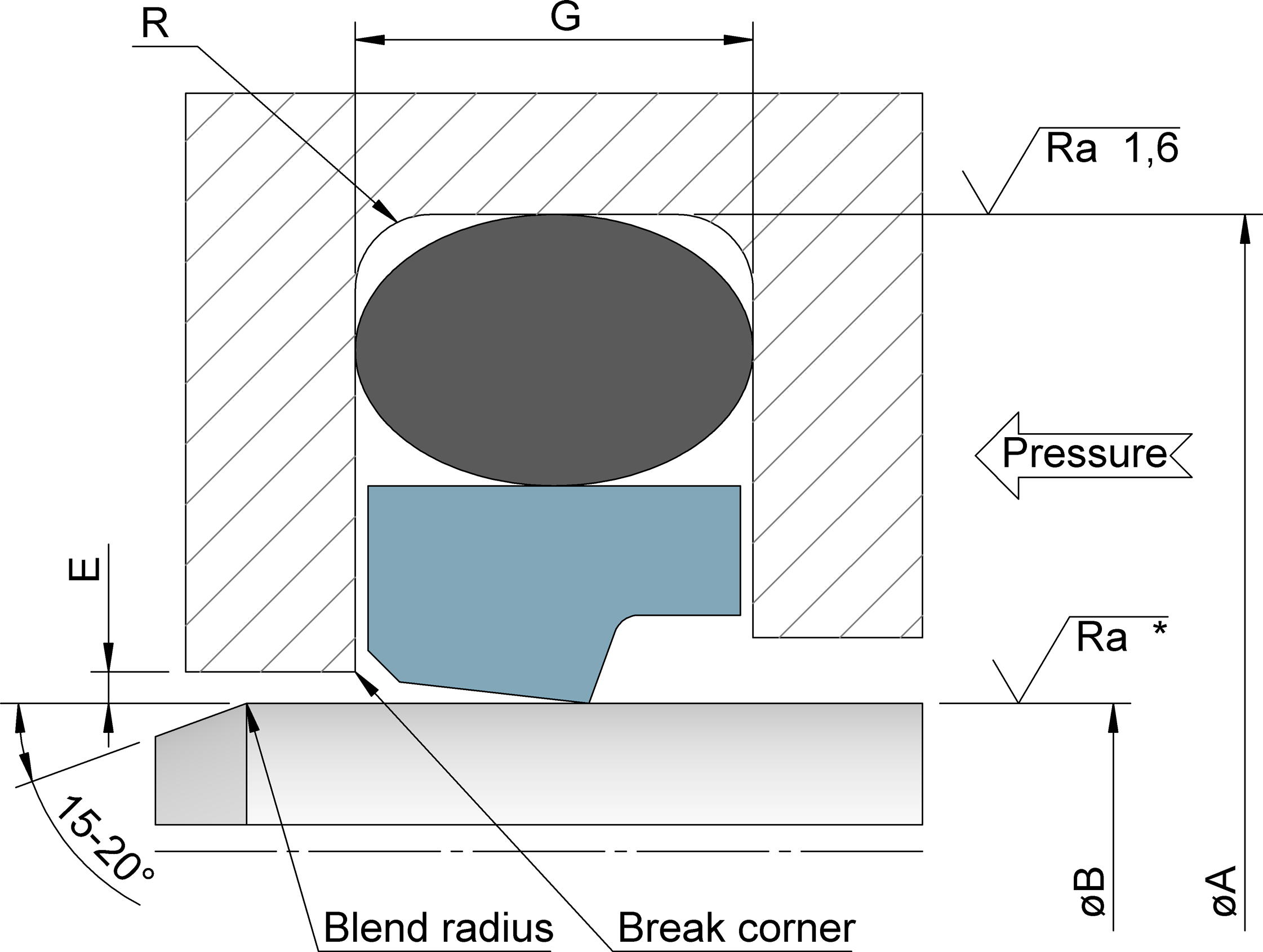

Technical details

Here you can see the technical details

-

Ra max (0.2 μm)

-

Rz max (1.25 μm)

-

Rp max (0.63 μm)

-

Tp = 50 - 70% at depth of p= 0.25 Rz

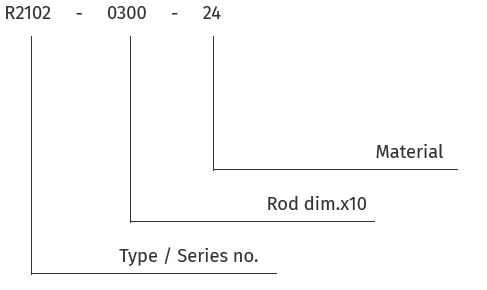

| Series | Rod øB f8/h9 | øA H11 | G + 0,2- 0 | R | Max radial Clearance | O-Ring | |||||||

| Heavy | Standard | Light | 16 MPa | 26 MPa | 32 MPa | 40 MPa | Series | Cross sect. | |||||

| R21 | 00 | - | 3 - 7,9 | 8 - 18,9 | øB + 4,9 | 2,2 | 0,3 - 0,5 | 0,35 | 0,30 | - | - | 000 | 1,78 |

| 01 | - | 8 - 18,9 | 19 - 37,9 | øB + 7,3 | 3,2 | 0,5 - 0,8 | 0,40 | 0,35 | - | - | 100 | 2,62 | |

| 02 | 8 - 18,9 | 19 - 37,9 | 38 - 199,9 | øB + 10,7 | 4,2 | 0,8 - 1,2 | 0,50 | 0,40 | 0,30 | - | 200 | 3,53 | |

| 03 | 19 - 37,9 | 38 - 199,9 | 200 - 255,9 | øB + 15,1 | 6,3 | 1,2 - 1,5 | 0,55 | 0,45 | 0,35 | 0,30 | 300 | 5,33 | |

| 04 | 38 - 199,9 | 200 - 255,9 | 256 - 649,9 | øB + 20,5 | 8,1 | 1,5 - 2,0 | 0,60 | 0,50 | 0,40 | 0,40 | 400 | 7,00 | |

| 05 | 200 - 255,9 | 256 - 649,9 | 650 - 999,9 | øB + 24,0 | 8,1 | 1,5 - 2,0 | 0,70 | 0,60 | 0,55 | 0,50 | 400 | 7,00 | |

| 06 | 256 - 649,9 | 650 - 999,9 | - | øB + 27,3 | 9,5 | 2,0 - 3,0 | 0,75 | 0,65 | 0,60 | 0,55 | - | 8,40 | |

Max radial clearance is based on DanaFlon 24 and 100 °C

For other hi-filled Danaflon compounds the clearance should be reduced with 10%

Clearance: At Pressure > 40 MPa use diameter tolerance H7/f7 (Bore/Rod)

Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.