Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.

Heavy DanaStep R310 is a heavy version of DanaStep. Heavy DanaStep is designed for heavy industry like hydraulic presses and even steel mills. Heavy DanaStep has the well-known profile that enables the seal to draw liquid back into the system.

With two Dana Steps in tandem combined with a double wiper, there is zero leakage in almost any application. Specially when Heavy DanaStep is made in our new materials based on modified PTFE, DanaFlon 24, DanaFlon 45 and DanaFlon 51 an optimal form stability and extrusion resistance is achieved.

Advantages:

APPLICATION EXAMPLES

Working conditions:

Frequently used Material DanaFlon | |||||

|---|---|---|---|---|---|

Seals, intensive movement High pressure | –200 to +260 °C | –200 to +260 °C | –200 to +260 °C | –200 to +260 °C | –200 to +260 °C |

Basis material | PTFE | Modified PTFE | Modified PTFE | PTFE | Modified PTFE |

DanaFlon | 24 | 25* | 45 | 55 | 51* |

Filler | Bronze & Additives | Bronze & Additives | Carbon fibre | Glass & MoS2 | Glass & MoS2 |

Colour | Brownish | Brownish | Dark Gray | Light Gray | Light Gray |

Extreme form stability and extrusion resistance | Yes | Yes | Yes | Yes | Yes |

Lubricating media | Yes | Yes | Yes | Yes | Yes |

Extreme wear resistance | Yes | Yes | Yes | Yes | Yes |

Wide range of media | No | No | Yes | Yes | Yes |

Non-lubricating media | No | No | Yes | Yes | Yes |

Food applications | No | No | No | No | No |

Conforms to food regulation | No | No | No | No | No |

*DF25 is similar to the well known DF24 and *DF51 is similar to the well known DF55, but they has even higher formstability against extrusion.

The Rubber-Profile-Rings may limit the temperature range and need to be compatible with the media.

The performance of the seal will always depend on the total picture of working conditions.

Verifying the performance of the seal can only be done by test at the actual working conditions.

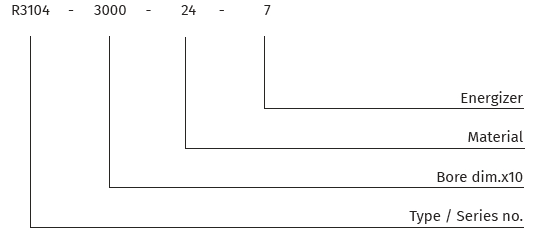

Heavy DanaStep R310

Here you can see the technical details

Heading #3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

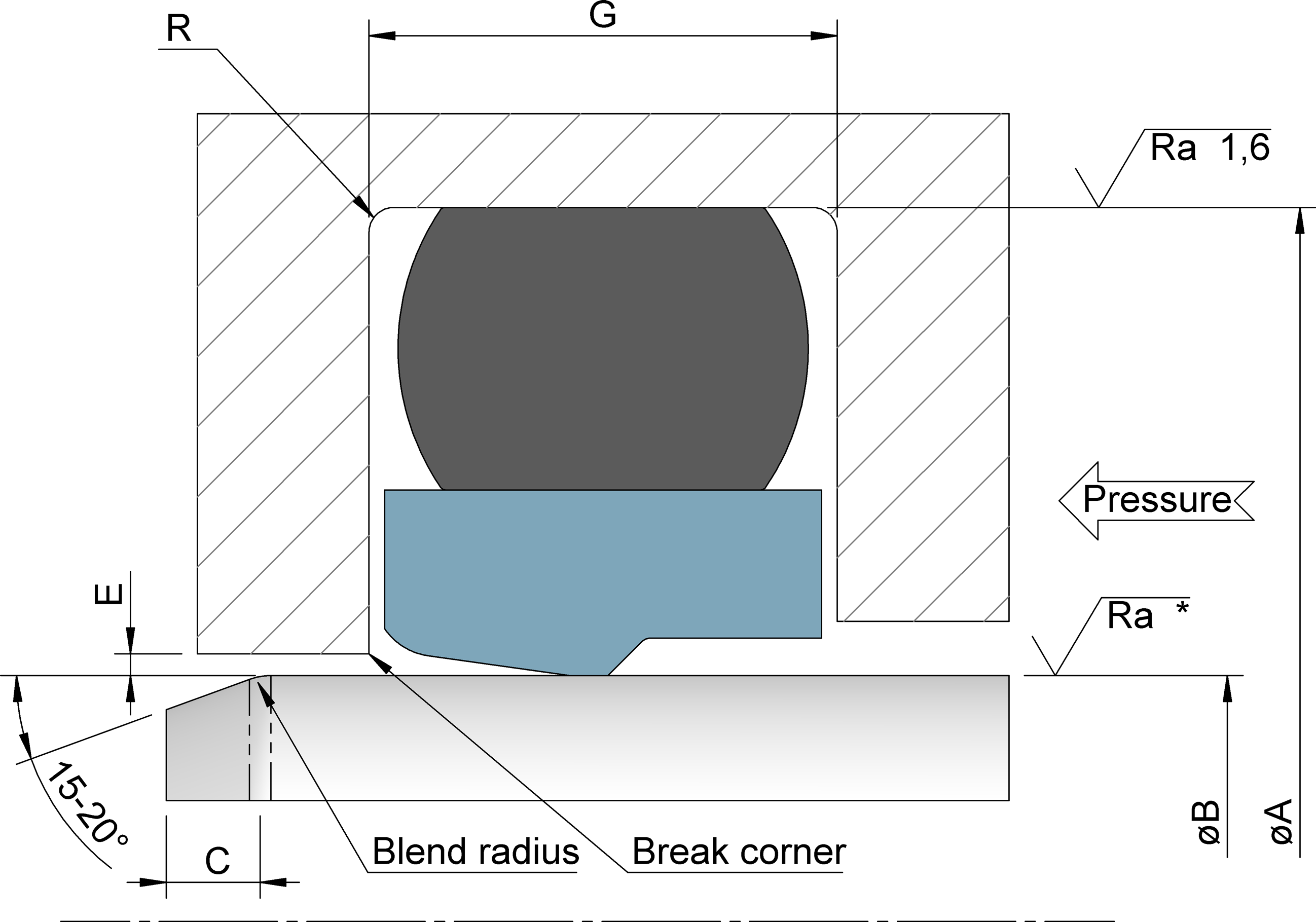

Serie | Rod | øA H8 | G + 0,2– 0 | R | C | Max radial Clearance | ||||

øB f8 | 16 MPa | 26 MPa | 32 MPa | 40 MPa | ||||||

R31 | 02 | 100 – 200 | øB + 20 | 10,0 | 0,4 | 7,5 | 0,75 | 0,50 | 0,40 | 0,40 |

03 | 220 – 300 | øB + 25 | 12,5 | 0,4 | 10 | 0,75 | 0,65 | 0,55 | 0,50 | |

04 | 300 – 540 | øB + 30 | 15,0 | 0,8 | 12 | 0,75 | 0,65 | 0,55 | 0,50 | |

05 | 530 – 690 | øB + 35 | 17,5 | 1,2 | 12 | 0,75 | 0,65 | 0,55 | 0,50 | |

06 | 690 – 2000 | øB + 40 | 20,0 | 1,2 | 15 | 0,80 | 0,70 | 0,60 | 0,55 | |

Max radial clearance is based in DanaFlon 24 and 100°C. For other hi-filled DanaFlon compounds please ask Dana-Seals A/S.

Clearance: At pressure >40Mpa use diameter tolerance H7/f7 (Bore/Rod.)

7 NBR

8 FPM

Delivery times

For special requests, please complete our Request form or call us on +45 4922 4400.

Ⓒ 2024 - All Rights Are Reserved

Please fill in the form below and we would appreciate it if you attach eventual drawings of hardware or seals to clarify technical demands.