CASE: CUSTOMIZED CRYOGENIC GAS PTFE-SEAL

Custom-made spring for cryogenic seal-solution

When complex conditions call for tailor-made solutions

There are no simple solutions to complex problems. This is especially true when it comes to

cryogenic gas seals. Standard seals easily fall short if there are too many complex constraints

involved. It takes a supplier with years of experience and expertise to develop customized

seal solutions for a cryogenic environment. Such a supplier is Dana-Seals.

CASE: CUSTOMIZED CRYOGENIC GAS PTFE-SEAL

Background

The client turned to Dana-Seals when facing a challenge with a seal for an engine fuelled by LNG. No standard PTFE spring-energized seals lived up to the client’s demand: The size of the motor is gigantic, with static and vibrating movements. The gas pressure is 350 bar and the working temperature -162°C. On top of this, a pressure from behind

called for a supporting ring in the spring groove.

CASE: CUSTOMIZED CRYOGENIC GAS PTFE-SEAL

Background

The client turned to Dana-Seals when facing a challenge with a seal for an engine fuelled by LNG. No standard PTFE spring-energized seals lived up to the client’s demand: The size of the motor is gigantic, with static and vibrating movements. The gas pressure is 350 bar and the working temperature -162°C. On top of this, a pressure from behind

called for a supporting ring in the spring groove.

Solution

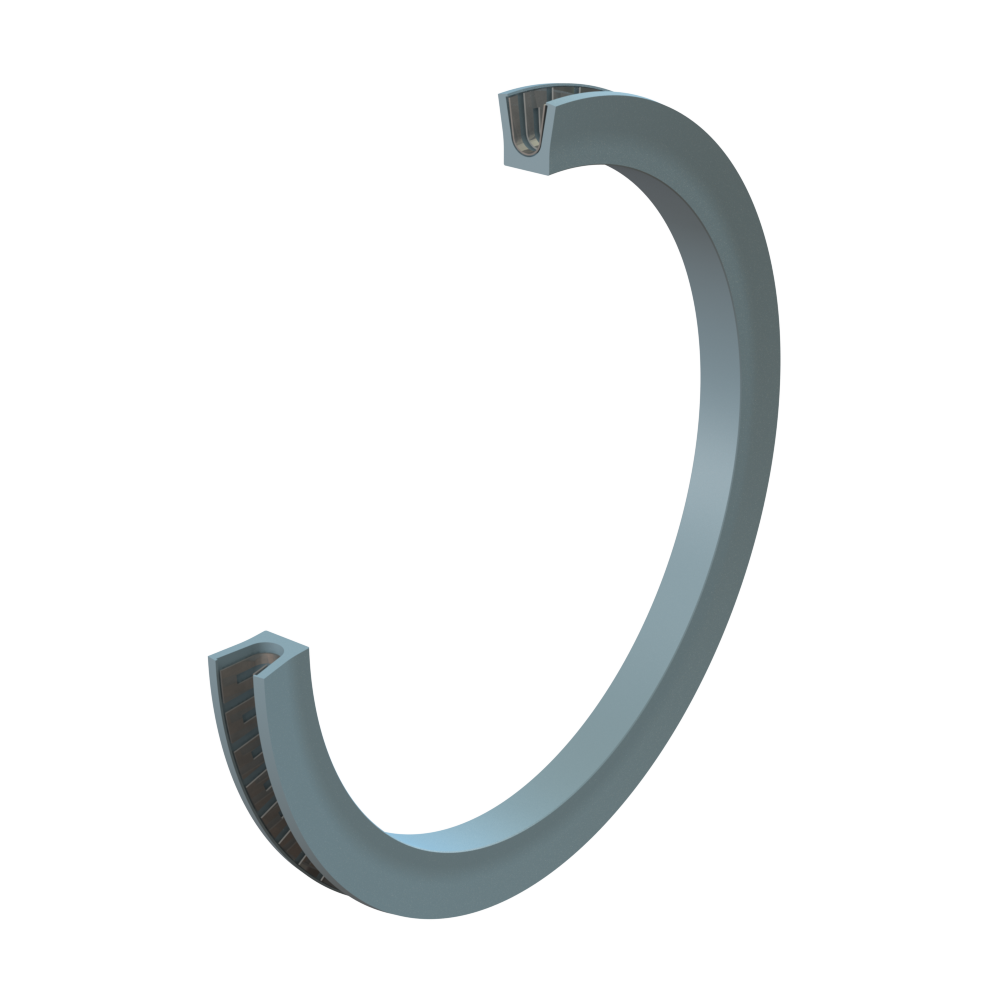

Normally, a powerful helical spring is a sufficient sealing solution in cryogenic gas applications. This applies to one part of the unit (see figure 1.) However, in another part of the equipment, a seal is having high pressure from behind. Due to this pressure, even a powerful helical spring would be destroyed.

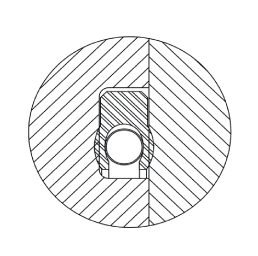

Asger Stryhn Rasmussen therefor came up with the idea to apply a V-shaped spring. In that way a supporting ring could be applied in the spring grove. The seal is then supported when having pressure from behind. However, the spring force of a normal V-spring is not sufficient. Therefore, two springs are used on top of each other. This solution is seen in fig. 2.

Research and development

“At DanaSeals we take pride in the fact, that our clients invite us into their R&D processes.”, Asger Stryhn Rasmussen tells. “Dana-Seals do not only customize PTFE compounds, as well as supply standard products. We also produce both standard and tailor-made springs to be used as energizers in our seals.” This combination made all the difference in this case. In the end, the solution proved to be able to exceed the

client’s demands with a couple of hundred bars and -195°C in the testing environment, proving this not only to be a sufficient solution for the gas engine at hand, but also R&D for future demands in the increasingly demanding cryogenic environment.

fig.1:

To seal efficiently against gas, a powerful helical spring is applied.

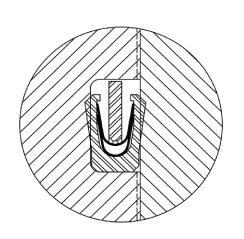

fig.2:

As the seal also will have pressure from behind, the choice was to use two V-shaped springs in the spring groove.

Facts about the cryogenic gas PTFE-seal

-

Gas pressure - Work 350 bar

-

Gas Pressure - Test 525 bar

-

Temperature - Work -162 C

-

Temperature - Test -195 C

-

Media Liquid LNG

-

Media - Test N2

-

Movement Static/shaking with a huge engine

The solution proved to be able to exceed the client’s demands with a couple of hundred bars and -195°C in the testing environment.